- Description

- Formats

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

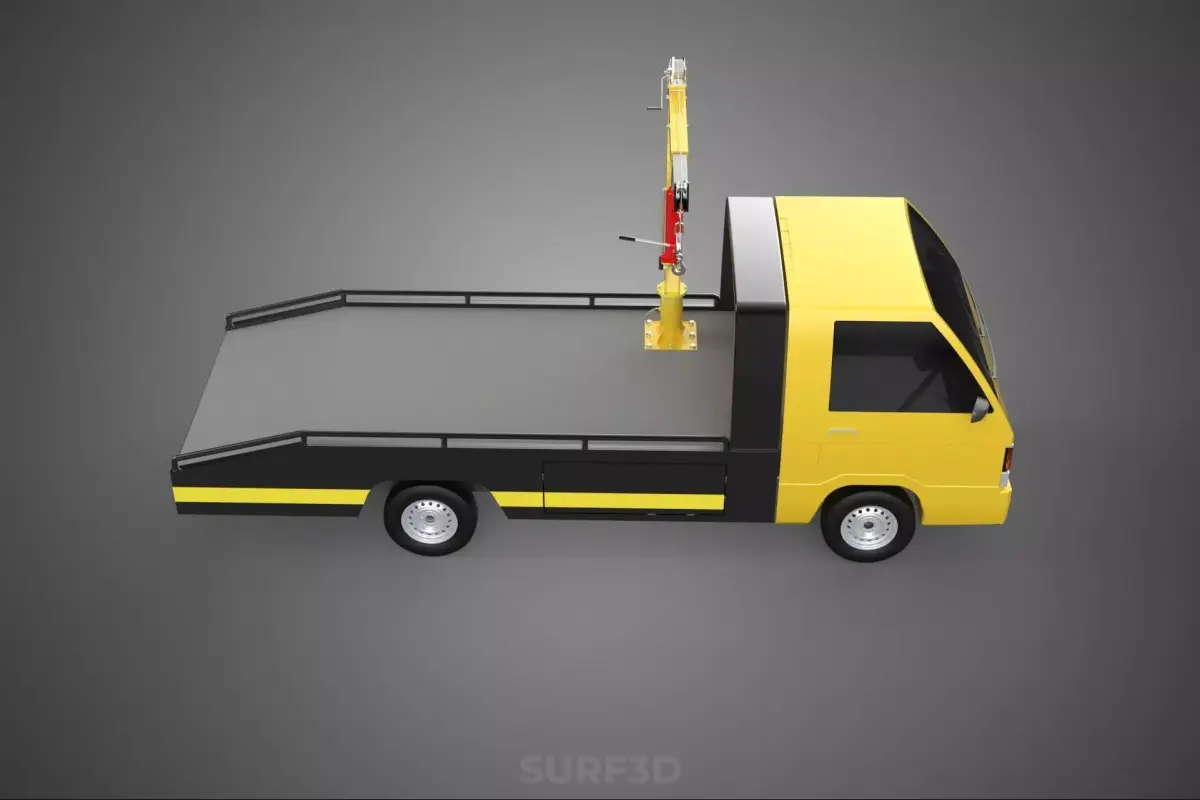

A Roadside Service Tow Truck with Overhead Rear Recovery Lifting Crane is a highly specialized heavy-duty vehicle engineered for the complex recovery, uprighting, and repositioning of large or incapacitated vehicles from challenging environments. This class of tow truck is distinct from conventional wreckers or flatbeds due to its prominent, hydraulically operated, multi-stage telescopic boom, or crane, mounted at the rear of the chassis, designed for significant vertical and horizontal lifting capabilities.

I. Core Function and Purpose

The primary function of this vehicle is to provide advanced recovery services in scenarios where standard towing methods are insufficient or unsafe. This includes, but is not limited to, uprighting overturned commercial vehicles (e.g., semi-trucks, buses), heavy construction equipment, or large cargo loads, particularly after accidents, rollovers, or when vehicles become submerged or stuck in difficult terrain (e.g., ditches, embankments, soft ground). Its robust lifting capacity and precise control allow for the extraction and careful manipulation of objects weighing many tons.

II. Key Components and Mechanism

- Overhead Rear Recovery Lifting Crane (Boom System): This is the defining feature. It typically comprises a series of nested, high-strength steel sections that extend telescopically, providing extensive reach and height.

- Rotation: Most cranes of this type are rotators, featuring a continuous 360-degree slewing (rotating) capability. This allows the boom to operate from any angle around the truck, providing unparalleled versatility in tight spaces or when access is limited.

- Articulation: Advanced designs may incorporate additional articulation points, allowing the boom to bend or knuckle, further enhancing its maneuverability and precision in complex recovery situations.

- Winch Systems: Multiple high-capacity hydraulic winches are integrated into the boom structure. These winches, often with independent controls and various line configurations (e.g., main and auxiliary lines), provide the immense pulling power necessary for uprighting, dragging, and securing heavy loads.

- Boom Head/Sheaves: The tip of the boom is equipped with multiple heavy-duty sheaves (pulleys) and attachment points, enabling diverse rigging setups for optimal load distribution and control.

- Stabilization System (Outriggers): To counteract the immense forces generated during lifting and ensure the stability of the vehicle, these trucks are equipped with heavy-duty hydraulic outriggers. These extend laterally and vertically from the chassis, creating a wide, stable base that distributes the load directly to the ground, preventing the truck from tipping or becoming unstable during high-load operations.

- Chassis and Power Train: Built upon a heavy-duty truck chassis, often with multiple axles for enhanced weight distribution and stability, these vehicles are powered by powerful diesel engines. A robust hydraulic system, driven by the truck's power take-off (PTO), supplies the energy required to operate the crane, winches, outriggers, and other auxiliary functions.

- Control Systems: Modern units feature sophisticated electronic control systems, often including remote control capabilities. This allows operators to precisely manipulate the boom, winches, and outriggers from a safe vantage point, ensuring optimal visibility and control during delicate maneuvers.

III. Operational Capabilities and Scenarios

The operational envelope of a Roadside Service Tow Truck with Overhead Rear Recovery Lifting Crane extends to:

- Major Accident Response: Clearing roadways quickly by uprighting and removing large, damaged vehicles or cargo.

- Off-Road and Water Recovery: Extracting vehicles from ditches, ravines, soft ground, or shallow water bodies where direct access for towing is impossible.

- Load Shift Correction: Righting or repositioning shifted cargo on trailers to prevent further incidents or facilitate transport.

- Heavy Equipment Relocation: Occasionally utilized for short-distance relocation or reorientation of non-operational heavy machinery in construction or industrial settings.

IV. Safety and Operator Expertise

The operation of such a powerful and complex machine demands highly specialized training and expertise. Operators must possess extensive knowledge of rigging techniques, load dynamics, weight distribution, stability principles, and safety protocols to ensure efficient and incident-free recovery operations, minimizing secondary damage and risks to personnel or the environment.

KEYWORDS: Tow truck, Wrecker, Recovery vehicle, Roadside assistance, Heavy-duty, Rotator, Crane, Lifting, Boom, Hydraulic system, Winch, Outrigger, Vehicle recovery, Accident recovery, Commercial vehicle, Heavy transport, Uprighting, Extraction, Salvage, Specialized vehicle, Emergency services, Professional operator, Stability, Rigging, Telescopic boom, Chassis, Hydraulic power, Industrial applications, Load manipulation, Site recovery.

Features

- Animated

- Rigged

- Ready for 3D Printing

- VR / AR / Low-poly

- PBR

- Textures

- Materials

- UV Mapping

- Unwrapped UVs: Unknown

- Geometry: -

- Polygons: 739,070

- Vertices: 561,254

credited to its original author, «SURF3D». CGhub does not claim copyright ownership over the content used.

- 3D Studio ()20.7 MB

- Blender ()65 MB

- AutoCAD ()31.4 MB

- Collada ()119 MB

- Autodesk FBX ()21.8 MB

- Rhinoceros 3D ()85.2 MB

- IGES ()68 MB

- OBJ () (2 files)72.3 MB

- 3D ACIS ()80.9 MB

- Stereolithography ()35.2 MB

- Autodesk 3ds Max ()149 MB

- STEP ()37.9 MB

- Other 37.9 MB

- glTF ()21.6 MB

- Sketchup ()52.7 MB