- Description

- Formats

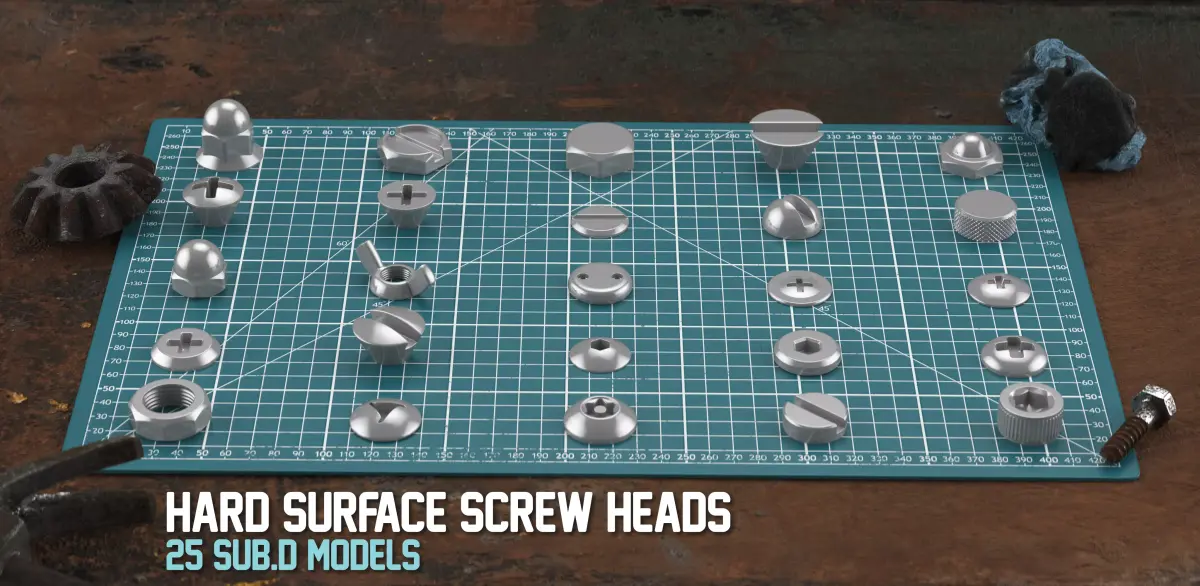

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

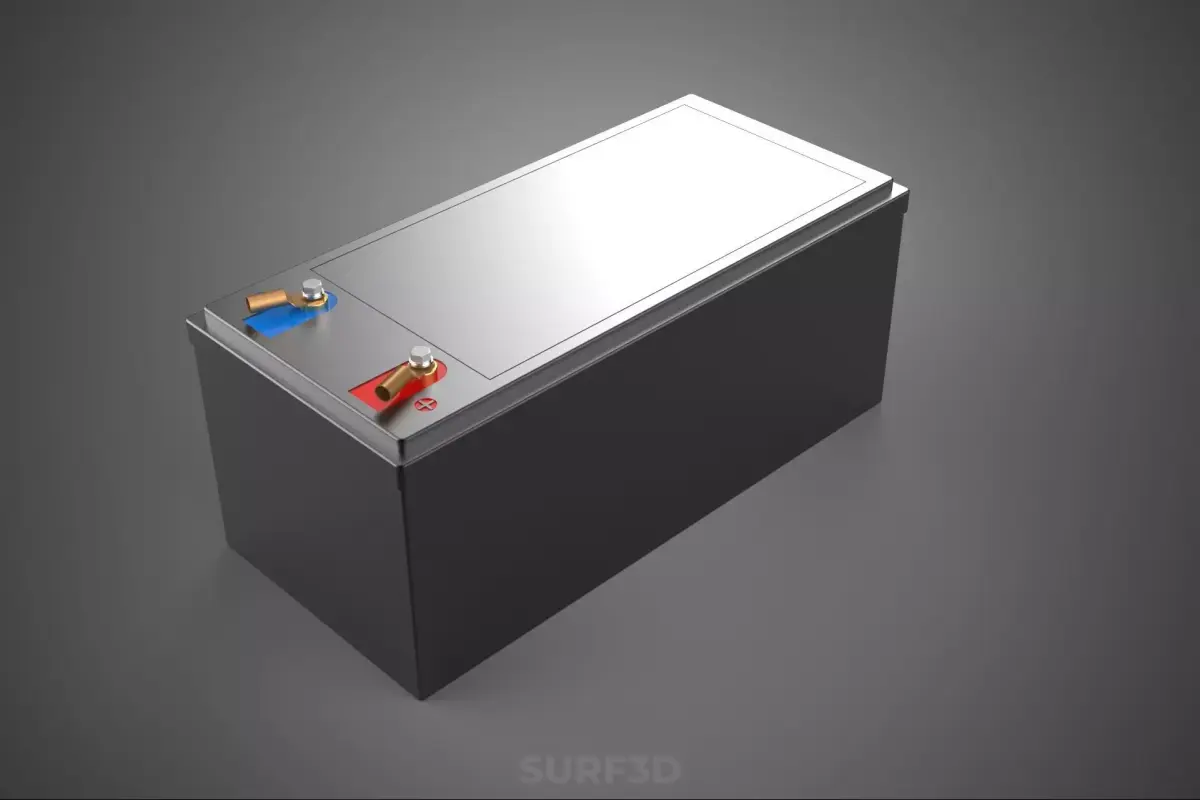

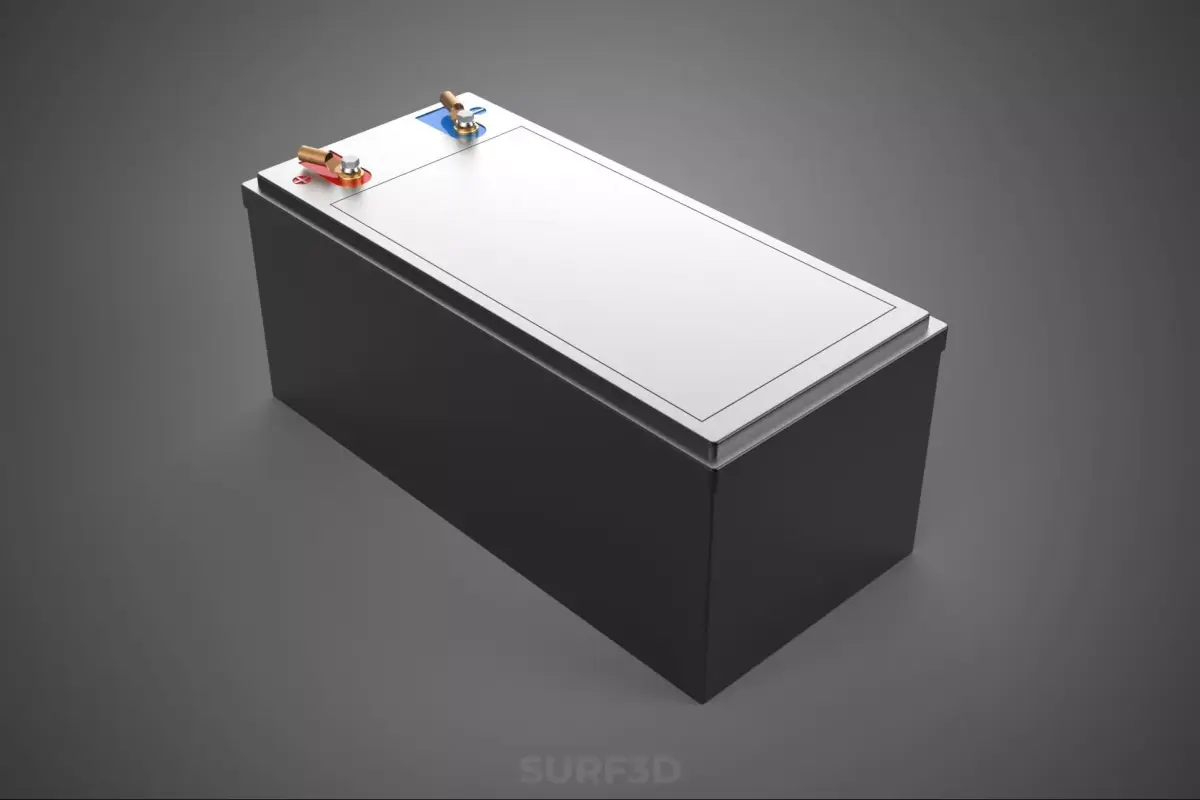

A standard industrial battery DC 12/24 Volt power supply energy storage system represents a critical component in various industrial, commercial, and utility-scale applications, providing reliable direct current (DC) power and robust energy storage capabilities. These systems are engineered to meet the rigorous demands of industrial environments, distinguishing themselves from consumer-grade batteries through their enhanced durability, longer cycle life, higher capacity, and ability to withstand challenging operating conditions.

Core Function and Definition:

At its fundamental level, such a system serves as both a primary or secondary DC power source and a reservoir for electrical energy. It converts stored chemical energy into electrical energy, delivering a stable 12-volt or 24-volt DC output. The power supply designation emphasizes its active role in supplying continuous power to connected loads, while energy storage highlights its capacity to store energy for later use, enabling operation during primary power outages, peak demand periods, or in off-grid scenarios. Standard implies adherence to common voltage specifications, physical form factors, and performance benchmarks widely adopted across industries.

Voltage Specifications (12V and 24V):

The specified 12V and 24V DC voltages are industry standards for a broad range of industrial equipment.

- 12-Volt Systems: Commonly utilized in smaller industrial vehicles (e.g., forklifts, golf carts), telecommunications equipment, emergency lighting, small uninterruptible power supplies (UPS), security systems, and portable power solutions. They are often chosen for their simplicity and compatibility with a vast array of DC components.

- 24-Volt Systems: Offer higher power output for the same current, reducing cable losses and improving efficiency for more demanding applications. These are prevalent in larger motive power applications, heavy-duty industrial machinery, marine systems, industrial automation, control systems, and as battery banks for renewable energy installations. A 24V system is typically achieved by connecting two 12V batteries in series.

Key Characteristics and Components:

- Battery Chemistry: While various chemistries exist, the most common for industrial DC 12/24V applications include:

- Lead-Acid Batteries: Comprising Flooded (wet cell), Absorbent Glass Mat (AGM), and Gel Cell (VRLA - Valve Regulated Lead-Acid) types. Lead-acid batteries are cost-effective, robust, and have a proven track record. Deep-cycle variants are specifically designed for repeated deep discharge and recharge cycles, crucial for energy storage applications.

- Lithium-Ion Batteries (Li-ion): Particularly Lithium Iron Phosphate (LiFePO4 or LFP) chemistries, are increasingly adopted due to their higher energy density, longer cycle life, faster charging capabilities, lower self-discharge rates, and lighter weight compared to lead-acid. They often require a Battery Management System (BMS) for optimal performance and safety.

- Capacity: Measured in Ampere-hours (Ah), indicating the amount of current a battery can deliver over a specific time. For industrial applications, capacities range from tens to thousands of Ah, depending on the power requirements and desired runtime.

- Design and Construction: Industrial batteries are built for durability, featuring rugged casings, vibration resistance, and often sealed designs to prevent electrolyte leakage and allow for flexible mounting. They are designed for deep cycling, meaning they can be discharged significantly before recharging without immediate degradation.

- System Integration: A complete industrial DC power supply energy storage system typically includes:

- Battery Bank: The core storage component.

- Charger/Rectifier: Converts AC utility power to DC to recharge the batteries and often provides simultaneous DC power to loads.

- Battery Management System (BMS): (Especially for Li-ion) Monitors voltage, current, temperature, and state of charge, balancing cells and protecting against overcharge, over-discharge, and thermal runaway.

- Monitoring and Control Systems: For remote management, performance tracking, and predictive maintenance.

- Safety Features: Circuit breakers, fuses, and ventilation systems (for flooded lead-acid) are integral for safe operation.

Applications:

These systems are vital in sectors requiring reliable and continuous DC power, including:

- Motive Power: Electric forklifts, pallet jacks, automated guided vehicles (AGVs), and other material handling equipment.

- Backup Power/UPS: Ensuring uninterrupted operation of critical control systems, telecommunications infrastructure, data centers (for DC equipment), and emergency lighting during grid outages.

- Renewable Energy Systems: Storing energy generated by solar panels or wind turbines for use when generation is low or demand is high, both in grid-tied and off-grid configurations.

- Industrial Automation: Powering Programmable Logic Controllers (PLCs), sensors, actuators, and other control elements in manufacturing plants.

- Telecommunications: Providing reliable DC power for remote base stations, central offices, and communication nodes.

- Marine and RV: Supplying power for onboard electrical systems.

Standards and Safety:

Adherence to industry standards (e.g., IEEE, UL, IEC) is paramount for ensuring safety, interoperability, and performance. This includes specifications for battery construction, performance testing, charging protocols, and safety measures against electrical hazards, thermal events, and electrolyte handling. Proper ventilation (for lead-acid), thermal management, and robust electrical protection are crucial design considerations.

Features

- Animated

- Rigged

- Ready for 3D Printing

- VR / AR / Low-poly

- PBR

- Textures

- Materials

- UV Mapping

- Unwrapped UVs: Unknown

- Geometry: -

- Polygons: 12,564

- Vertices: 10,460

credited to its original author, «SURF3D». CGhub does not claim copyright ownership over the content used.

- Blender ()1.77 MB

- Rhinoceros 3D ()1.68 MB

- Collada ()2.08 MB

- Autodesk FBX ()450 KB

- AutoCAD ()774 KB

- glTF ()435 KB

- OBJ () (2 files)1.1 MB

- Autodesk 3ds Max ()2.93 MB

- 3D Studio ()398 KB

- STEP ()689 KB

- Other 689 KB

- Sketchup ()694 KB

- 3D ACIS ()661 KB

- IGES ()1.26 MB

- Stereolithography ()638 KB