Description

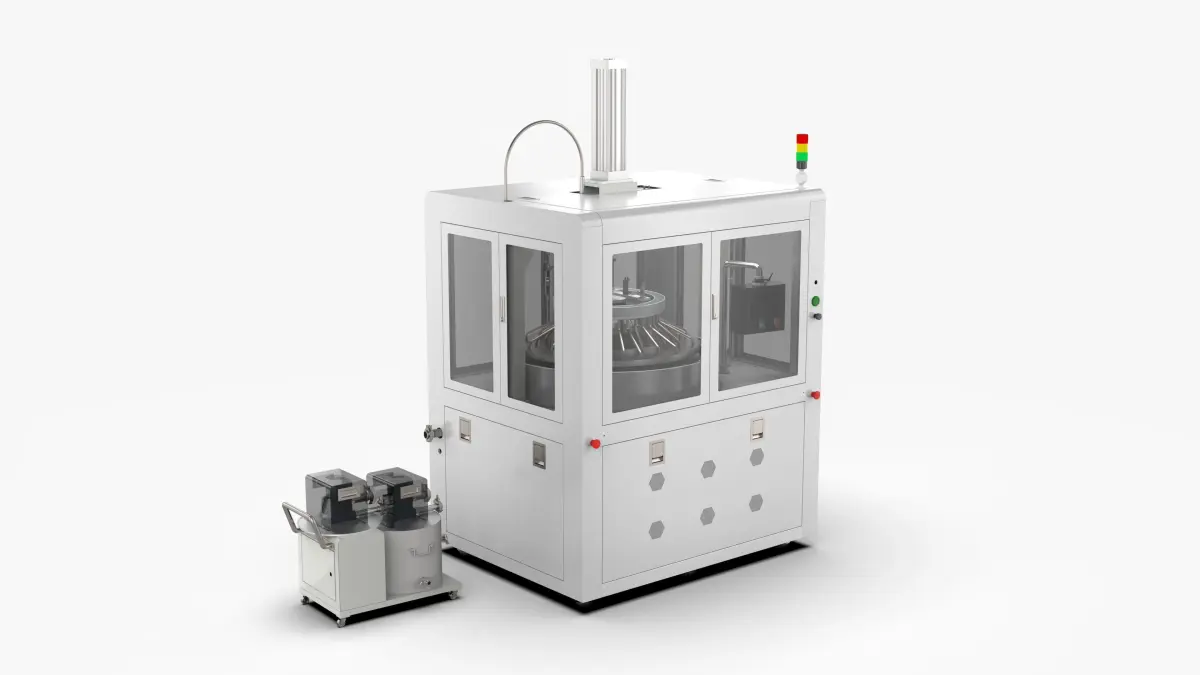

Automatic High Precision Glass Polishing Machine

Introduction

Non-standard automatic high-precision glass polishing machine (3D+2D+CAD engineering drawing+BOM list details)

The main purpose is mainly used for high-precision double-sided grinding of sapphire, blue glass, ceramic sheets, crystals, semiconductors and other hard and brittle materials /Polishing, especially for the processing of ultra-thin workpieces has obvious advantages.

Main features

- Precise pressure control: PLC+PT+electrical proportional valve+low-friction cylinder to achieve high-precision pressure closed-loop control;

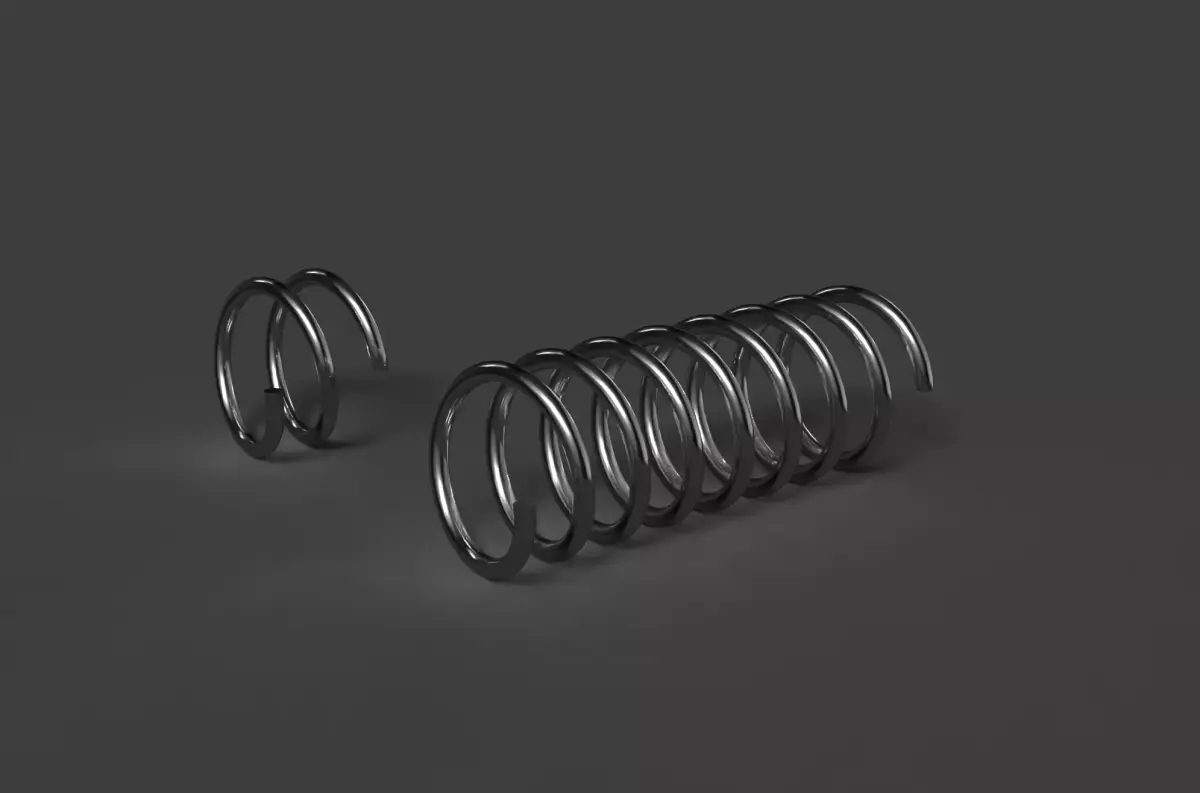

- Upper disk shock absorber: elastic connection method for vibration reduction applicable to both dynamic and static states;

- Precision transmission System: high-precision small backlash full gear transmission;

- Bottom plate support: high-precision plane fluid bearing support, large bearing capacity, stable operation, and maintenance-free;

- Pin gear transmission: internal and external gears adopt pin gear transmission to extend the use of the carrier Long life, easy maintenance, involute gear transmission can also be used;

- Transmission system: three motors are synchronously driven, and the speed of the upper plate, the lower plate, the ring gear, and the sun gear (both forward and reverse) can be arbitrary Setting, with recipe function.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 3,028,774

- Vertice: 9,086,322