Description

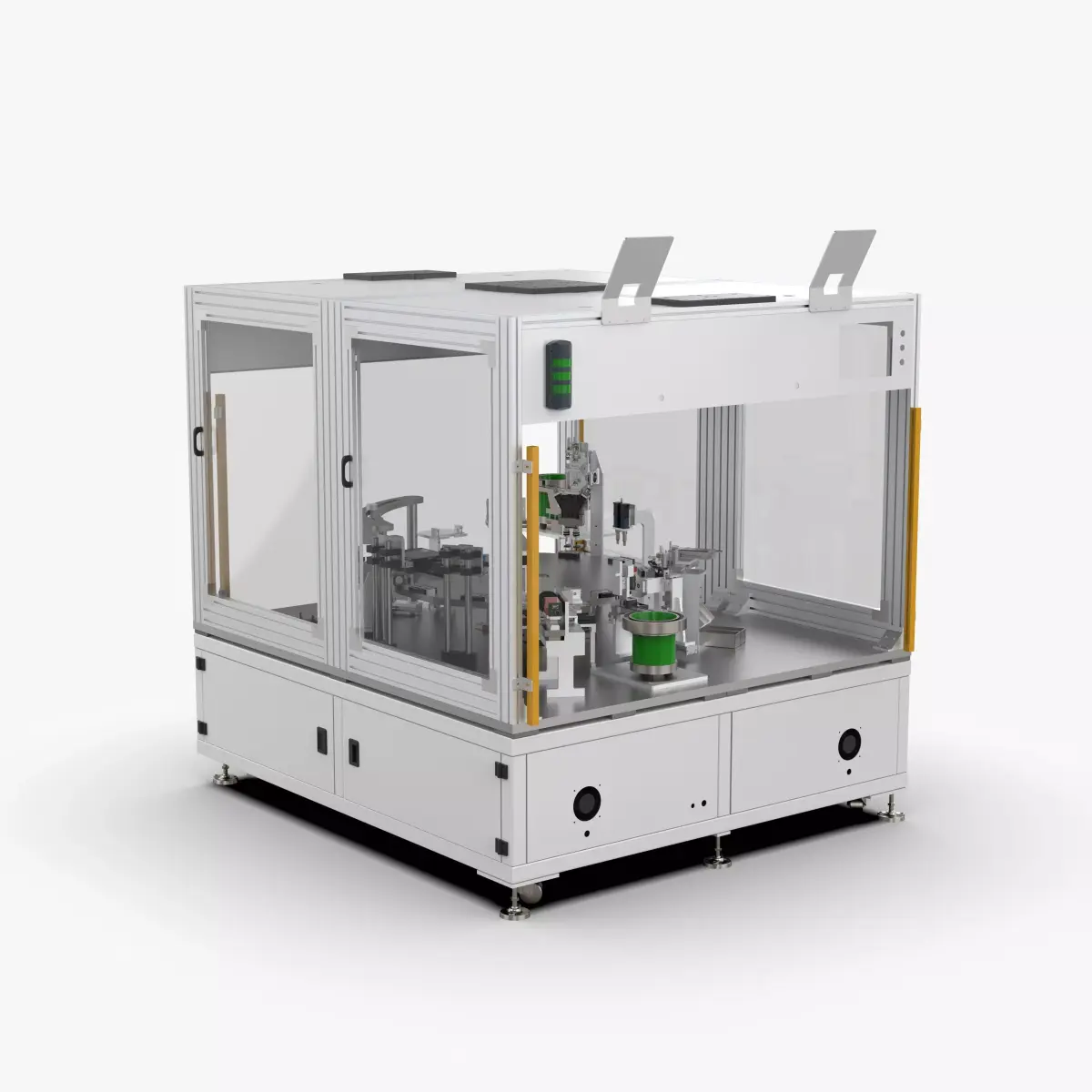

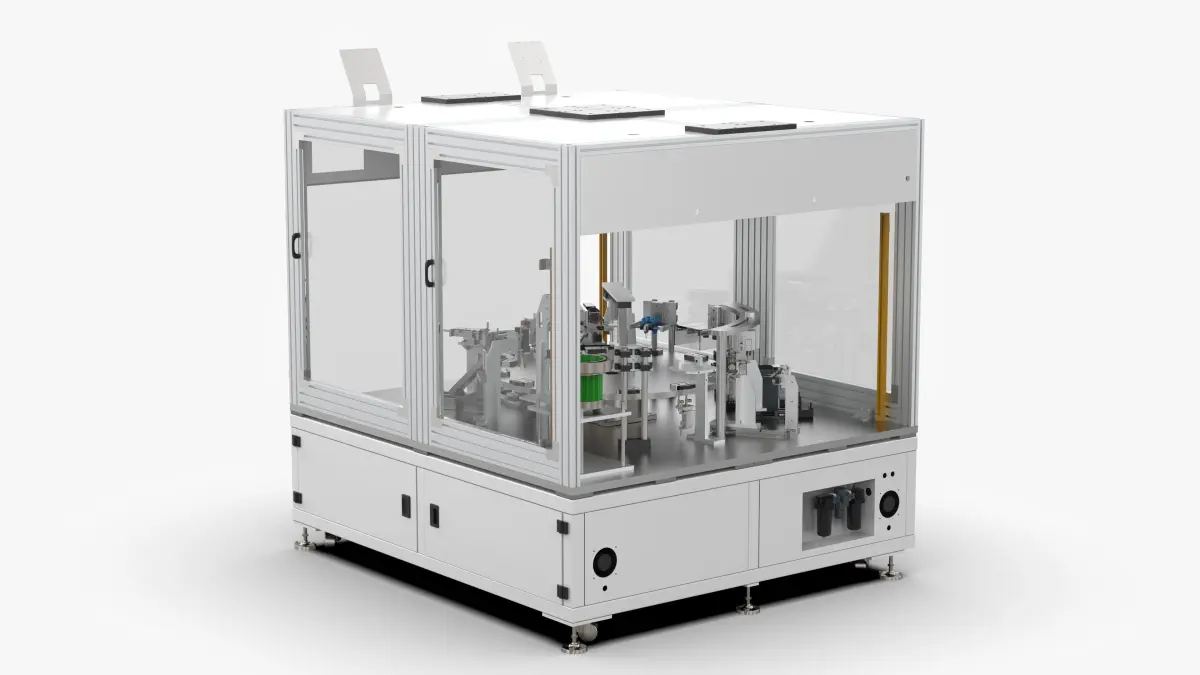

Automatic Injection Needle Assembly Dispensing Machine

Introduction

Automatic injection needle assembly and dispensing machine action description:

- Step 1: Base vibrating plate feeding, and a CCD to judge the front and back of the Base;

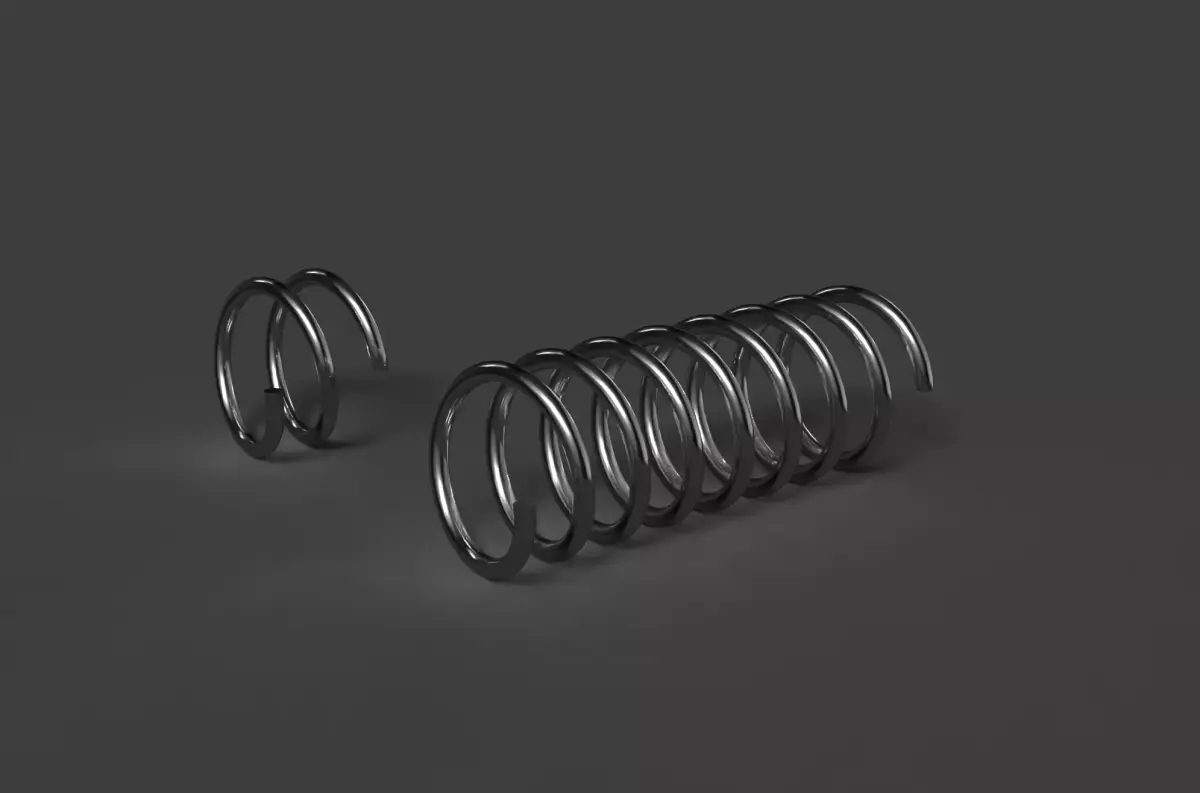

- Step 2: Insert the first needle tube, and a CCD to judge the front and back of the needle tube and whether it is present or not Bad;

- Step 3: Insert the second needle tube, and have a CCD to judge the forward and reverse of the needle tube and whether there is a defect;

- Step 4: Apply UV glue;

- Step 5: UV curing;

- Step 6: Apply airtight glue;

- Step 7: Strong air drying;

- Step 8: Silica gel on the nozzle;

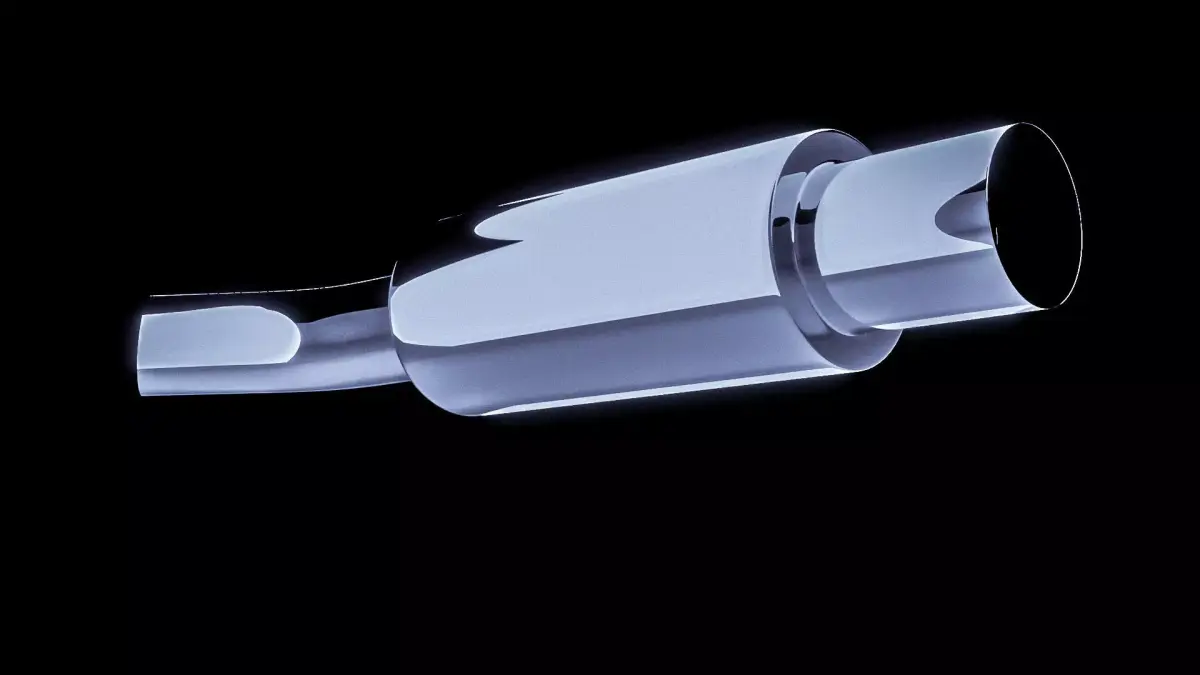

- Step 9: Cover pre-installation;

- Step 10: Cover pressing;

- Step 11: Finished product discharge (automatically distinguish OK & NG);

- Step 12: Repeat the above actions;

The working purpose of the injection needle assembly machine: The machine automatically feeds materials (needles, Base and Cover), and automatically assembles them.

Operation mode: disc type operation:

- C/T: Estimated 2pcs/5sec;

- Estimated size of the machine: 2000(L)*1800(W)*1800(H)mm.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 1,770,867

- Vertice: 5,312,601