Publication date: 2023-03-10

Automatic Plug-in Induction Vibration Feeding Soldering Machine 3D model

$89

License: Royalty Free License

3D Model details

- cgtrader Platform

- Animated

- Rigged

- Ready for 3D Printing

- VR / AR / Low-poly

- PBR

- Textures

- Materials

- UV Mapping

- Polygons: 1459052

- Vertices: 4,377,156

- Plugins used

- Geometry: Polygon mesh

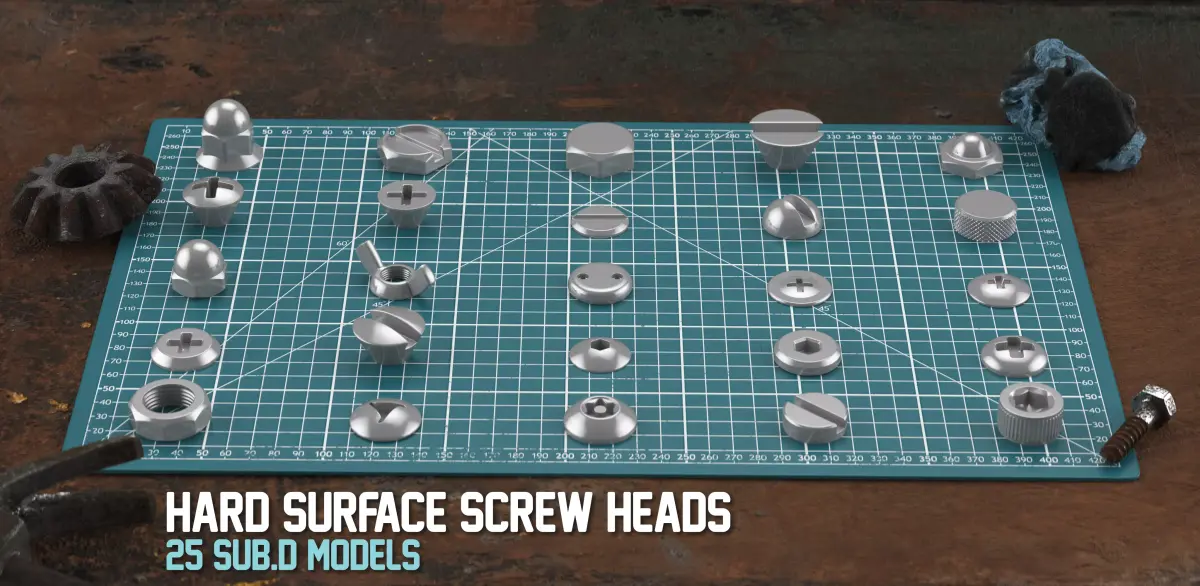

Similar models

Find the models you need