High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

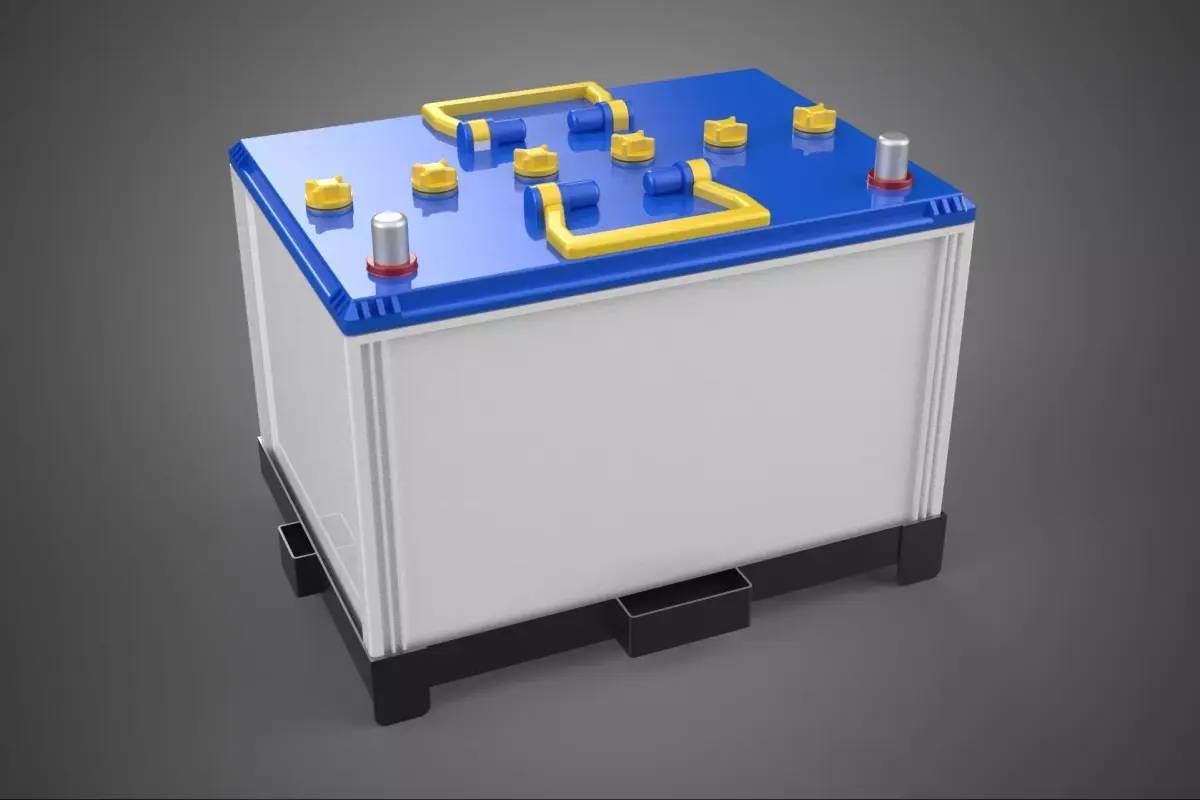

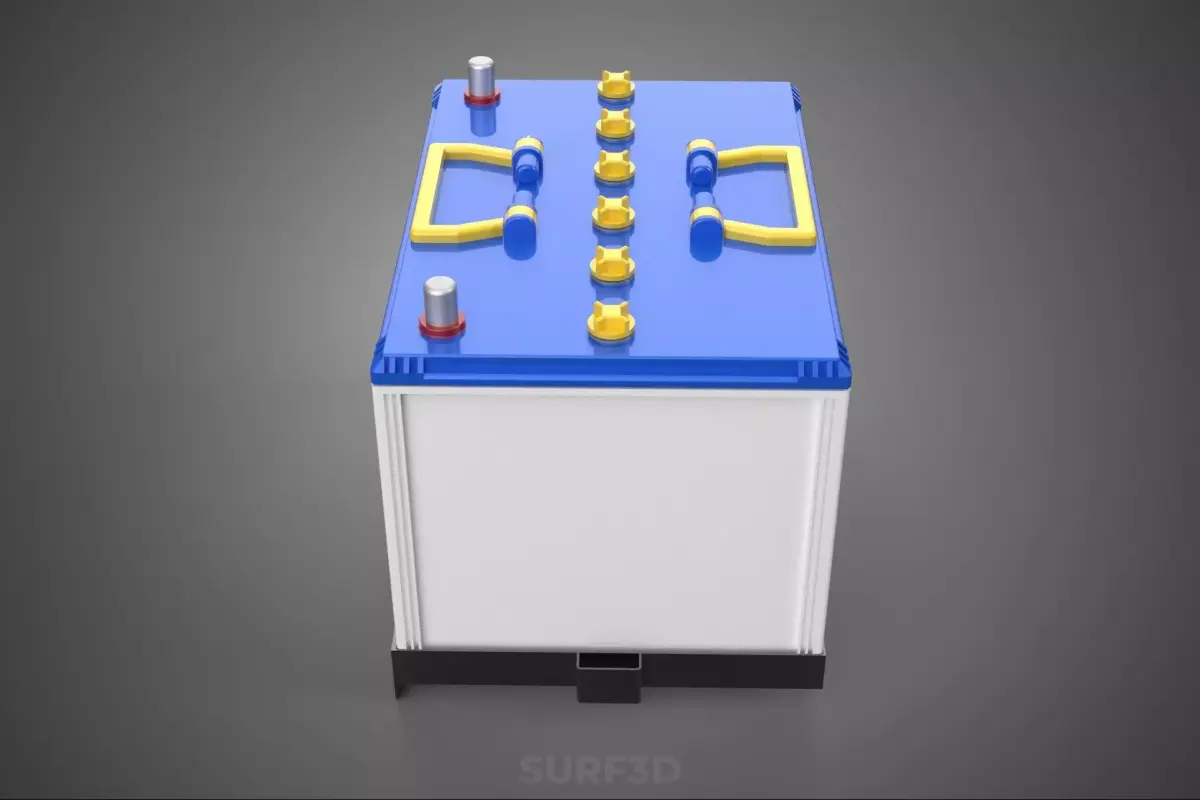

ACCUMULATOR AND MOUNTING SYSTEM FOR VEHICULAR APPLICATIONS

The component described by the title ACCU BATTERY ACCUMULATOR VEHICLE VOLT with BRACKET HOLDER MOUNT CASE refers to a complete vehicular energy storage assembly, consisting of the electrochemical device itself (the accumulator/battery) and its dedicated mounting and protective apparatus. This integrated system is fundamental to the operation of internal combustion engine (ICE) vehicles and serves as a critical component in hybrid electric vehicles (HEVs) and pure electric vehicles (EVs), though the chemistry and capacity differ significantly across these platforms.

Nomenclature and Function

The terms Accu, Battery, and Accumulator are generally used interchangeably in vehicular contexts to denote a rechargeable electrochemical cell or series of cells designed to store energy and deliver electrical power.

The primary function of the Vehicle Accumulator in standard ICE vehicles is threefold:

- Starting (Cranking): To provide a high burst of current (measured in Cold Cranking Amperes, CCA) required by the starter motor to initiate engine rotation.

- Lighting and Ignition (SLI): To power the vehicle's electrical accessories, lights, and ignition system when the engine is not running or the alternator is operating at low speed.

- Voltage Stabilization: To act as a buffer for the electrical system, absorbing voltage spikes and smoothing transients generated by the alternator or other high-load components.

### Battery Technology and Voltage Standards (VOLT)

Modern vehicular batteries predominantly operate at nominal system voltages, with 12 Volts (V) being the industry standard for light-duty vehicles and passenger cars. This 12V configuration is typically achieved by connecting six cells in series, each producing approximately 2.1 volts when fully charged. Heavy-duty applications, commercial transport, and large marine vessels often utilize 24V systems.

The most common chemistries employed include:

- Flooded Lead-Acid (Wet Cell): The traditional and most cost-effective type, requiring maintenance (periodic addition of distilled water).

- Valve-Regulated Lead-Acid (VRLA): Includes Absorbent Glass Mat (AGM) and Gel batteries. These are sealed, maintenance-free, and offer superior vibration resistance and deep-cycle performance, making them ideal for vehicles with Start-Stop technology.

- Lithium-Ion (Li-ion): Increasingly utilized in high-performance or specialized applications (e.g., Formula 1, high-end sports cars) due to their high energy density and low weight. They are standard for the main drive batteries in HEVs and EVs, though a separate 12V Li-ion or AGM battery often manages auxiliary systems.

### The Mounting and Containment System (BRACKET HOLDER MOUNT CASE)

The Bracket, Holder, Mount, and Case components comprise the mechanical infrastructure necessary to integrate the battery safely and securely into the vehicle chassis. This system is crucial for:

- Physical Security and Vibration Damping: Vehicle operation subjects the battery to significant acceleration forces, impacts, and constant vibration. The Case (the outer housing of the battery itself) and the surrounding Holder/Tray (a rigid containment structure, often plastic or coated steel) must prevent physical damage. The Bracket/Mount uses clamps or hold-down rods attached to the chassis frame to ensure the assembly cannot shift, which is mandated by safety regulations.

- Thermal Management: The holder system assists in insulating the battery from excessive engine heat or, in cold climates, sometimes incorporates provisions for heating elements to maintain optimal operating temperature.

- Corrosion and Environmental Protection: Lead-acid batteries emit corrosive hydrogen gas during charging and contain sulfuric acid electrolyte. The mount and case system provides a barrier, preventing electrolyte spills from damaging surrounding components and shielding the battery terminals from road spray, dirt, and debris.

- Standardization and Fitment: Battery dimensions (length, width, height) and terminal location are standardized by bodies such as the Battery Council International (BCI) or Deutsches Institut für Normung (DIN). The bracket and holder are engineered precisely to accept batteries conforming to these standardized groups, ensuring compatibility across different models and manufacturers.

In summary, the vehicular battery system with an integrated mounting apparatus represents a standardized, safety-critical assembly engineered to withstand the challenging mechanical and thermal environment of vehicle operation while providing reliable electrical power.

KEYWORDS: Accumulator, Battery, Vehicular Power, 12 Volt, SLI, Cold Cranking Amperes, Lead-Acid, AGM, VRLA, Lithium-Ion, Chassis Mount, Battery Holder, Containment Case, Bracket System, Vibration Resistance, Corrosion Protection, Battery Tray, Engine Bay, Electrical System, DIN Standard, BCI Group, Starter Motor, Voltage Stabilization, Rechargeable, Electrochemical Storage, Automotive Component, Start-Stop Technology, Power Buffer.

STL (Stereolithography, filesize: 1.17 MB), OBJ (OBJ, filesize: 1.91 MB), 3DS (3D Studio, filesize: 770 KB), DWG (AutoCAD, filesize: 1.25 MB), 3DM (Rhinoceros 3D, filesize: 7.82 MB), GLTF (glTF, filesize: 851 KB), SKP (Sketchup, filesize: 1.94 MB), FBX (Autodesk FBX, filesize: 799 KB), MAX (Autodesk 3ds Max, filesize: 8.08 MB), STP (STEP, filesize: 3.01 MB), DAE (Collada, filesize: 4.03 MB), BLEND (Blender, filesize: 2.71 MB), IGE (IGES, filesize: 6.08 MB), SAT (3D ACIS, filesize: 1.93 MB)