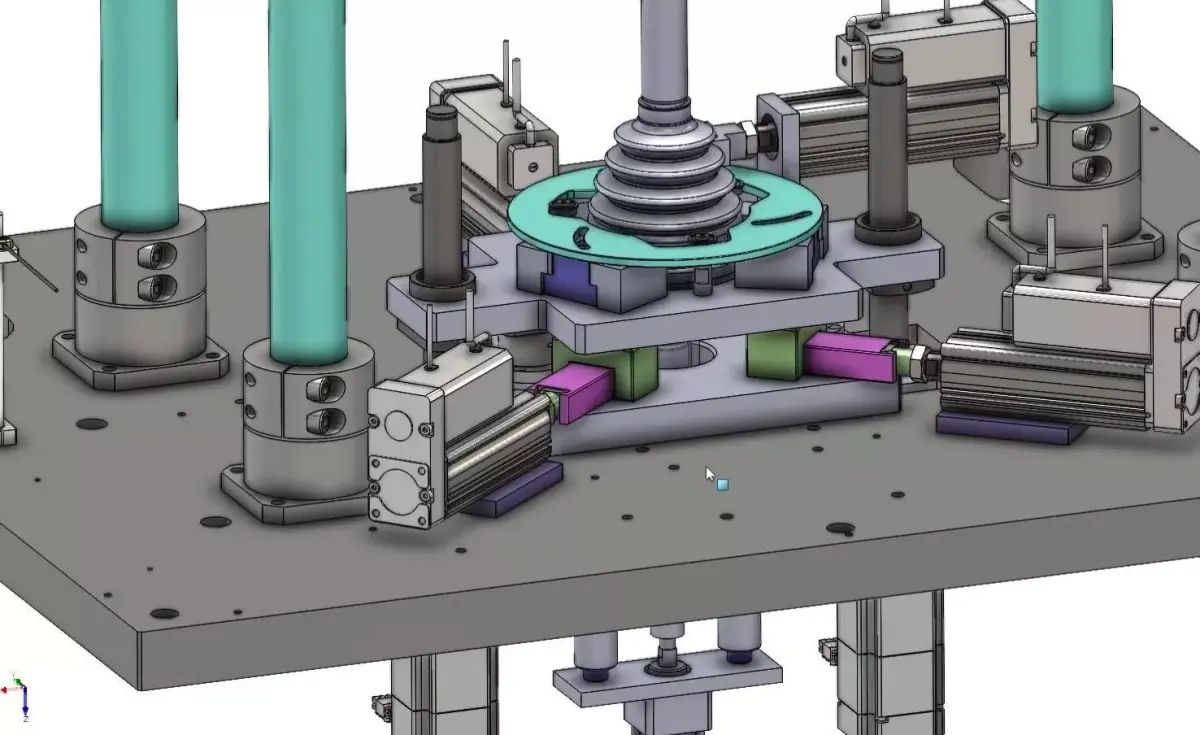

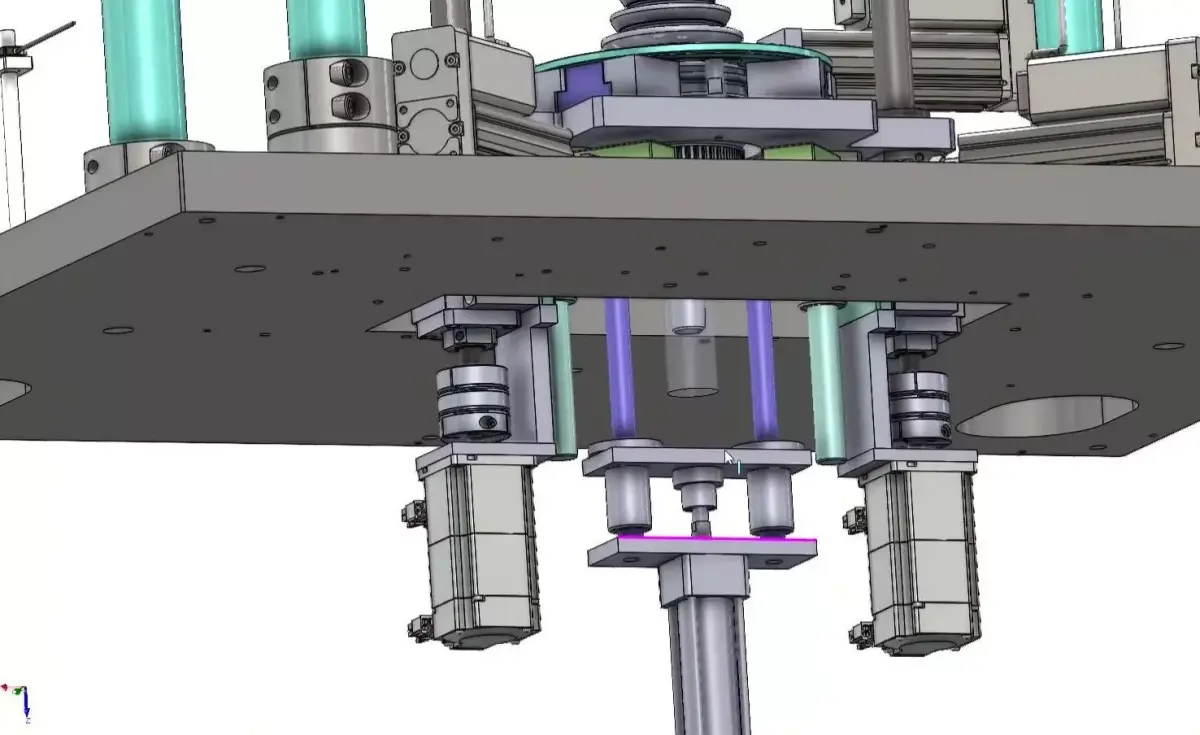

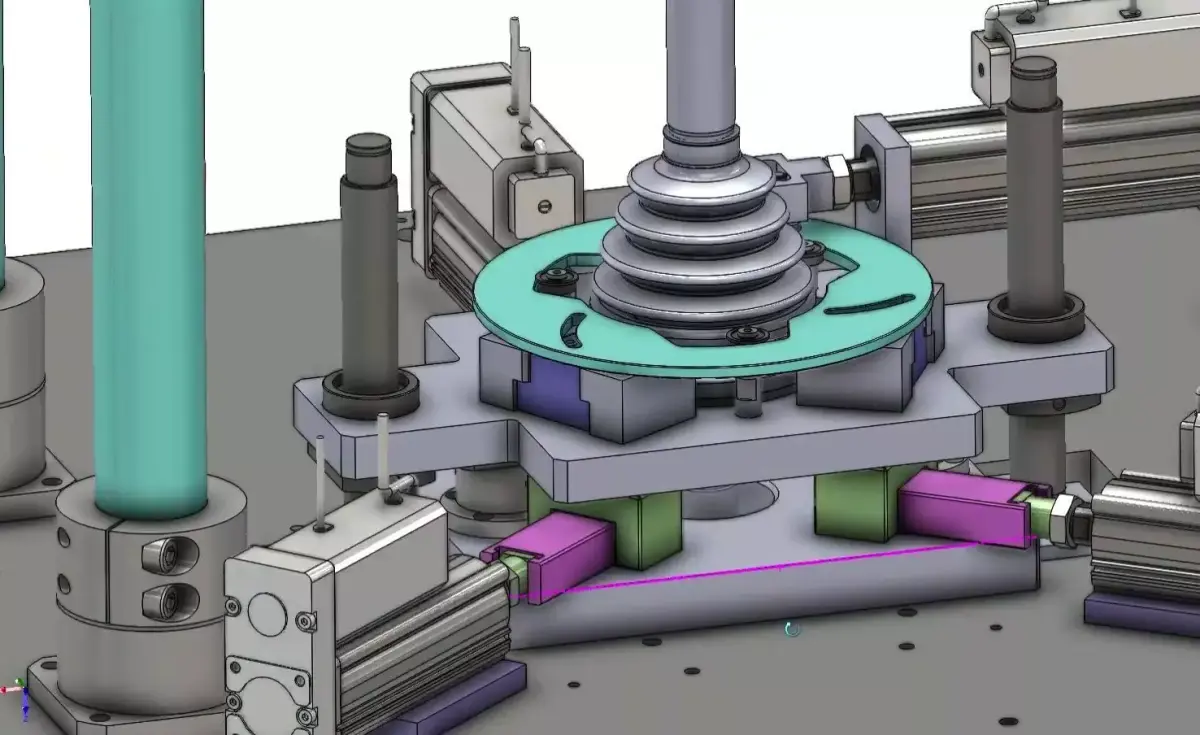

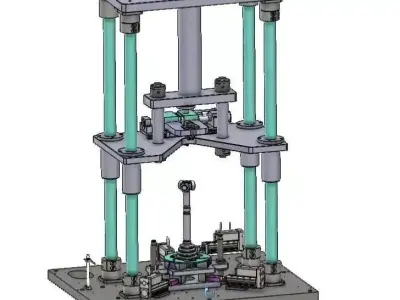

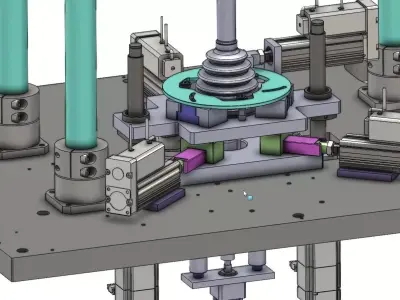

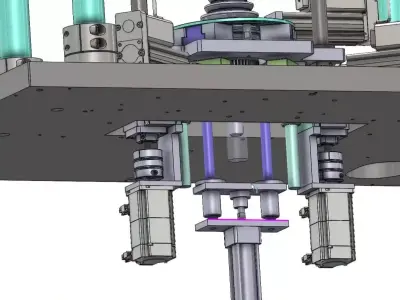

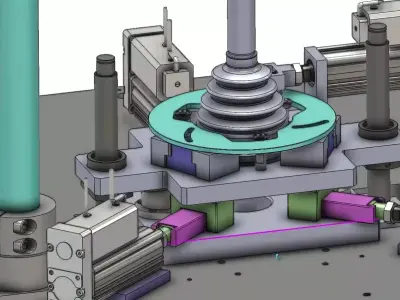

High-precision car steering joint assembly machine 3D CAD model designed for automated pressing operations in automotive manufacturing. The system clamps, aligns, and presses steering joints accurately using servo-driven mechanisms, integrated pressure sensing, and position detection to ensure correct assembly every cycle.Key Features• Dedicated machine for car steering joint press assembly• Servo screw–driven clamping jaws for adaptive diameter controlo Mandrel outer diameter range: 17–35 mm• Servo press system with adjustable stroke based on mandrel heighto Mandrel height range: 200–900 mm• Integrated pressure sensor to monitor press force in real time• Position sensor to verify correct press depth and alignment• Pullback chuck engages force point during pressing for stability Industrial-grade structure suitable for high-volume production linesTypical Applications• Automotive steering joint assembly• Precision press-fit operations• Automated automotive component lines• Machine design validation & factory layout planning

SLDPRT (SolidWorks, filesize: 41.2 MB), STL (Stereolithography, filesize: 17.3 MB), STP (STEP, filesize: 7.2 MB), IGE (IGES, filesize: 8.1 MB), X_T (Parasolid, filesize: 4.4 MB), OTHER (Other, filesize: 8.58 MB)