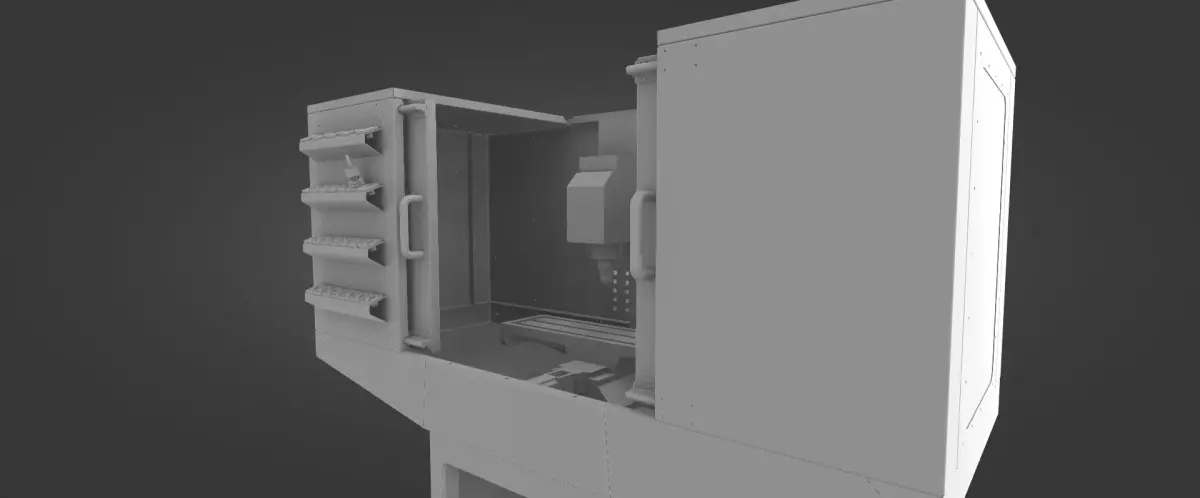

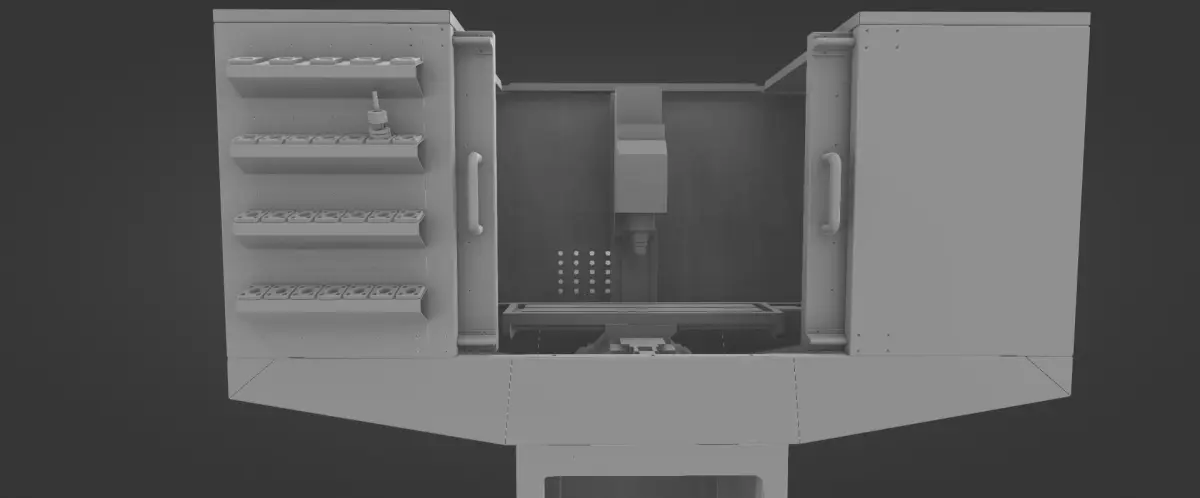

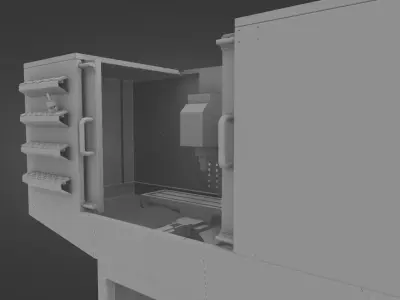

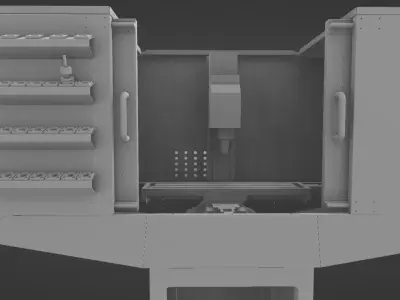

This is the standard enclosure we use for our CNC conversions. It is designed to fit the Grizzly G0704 / Optimum BF20 or clone machines. It fits most off the shelf CNC conversion kits as is, but we have come across a it with a slightly longer Y axis motor that needs a small cut made in the roof sheet metal to clear the column position.

Construction is relatively straight forward, with two options for the base tray - either welded seam (slightly nicer) or riveted seams (somewhat easier for a DIY job).There are .DXF and .STEP files provided to send to your local CNC laser cut / fold shop. The native Solid Works files are also provided, so you can tweak the design if needed. The acrylic windows have their own .DXF files for laser cutting.

The panels are mostly joined to each other using M5 screws and M5 rivnuts, and the windows are held in place with M4 button head screws and nyloc nuts.

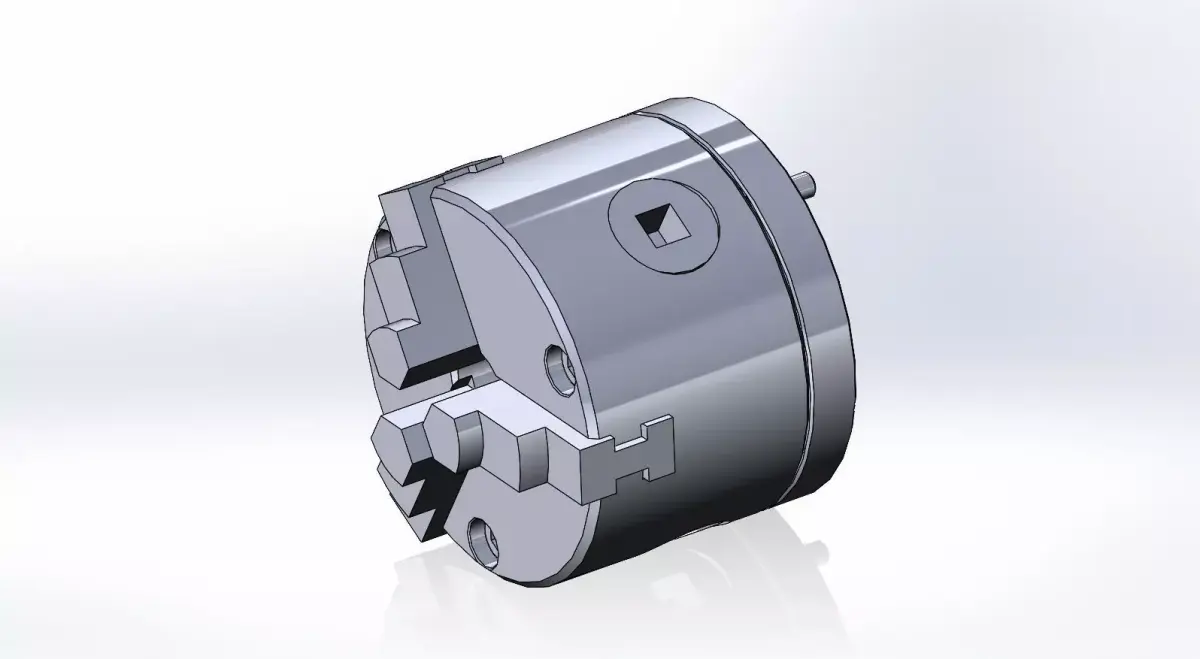

The doors run on SBR16-500L rails, and use the long SBR16LUU bearings. The handles are an off-the-shelf unit with 145mm hole centers.

NOTES:

- The welded machine riser has mounting holes that work with the kits we've fitted. We've seen some variance between machines and kits, so make sure your hole positions are correct for your particular set up.

- The holes to mount the tool racks are not modelled into the side panels. We use self drill / tap screws to fix these in place.

- There is a bank of cable gland holes on the back. Use as many as you need to, and then blank the others with blanking plugs (available very cheaply online).

- We use an M12 Machine foot. If you wish to use a different thread size, just change your bushes to suit.

- There are no engineering drawings included in this package - it's assumed that the parts will just be lasercut & folded and then bolted together, and the 3d model used as a reference if needed. If you get stuck feel free to fire me an email (email is quicker than a DM here) with any questions - I'm more than happy to help out.

- We use 1.15mm pre-galvanized steel for most of the panels to give improved resistance to flood coolant.

Native Formats: SLDPRT (SolidWorks, filesize: 74.4 MB)

Exchange Formats: IGE (IGES, filesize: 70.1 MB), SLDPRT (SolidWorks, filesize: 74.4 MB), X_T (Parasolid, filesize: 70.1 MB), DXF (DXF, filesize: 3.16 MB), PDF (PDF, filesize: 1.12 MB), STL (Stereolithography, filesize: 2.03 MB), HRD (High-Res Renderings, filesize: 11.1 MB)