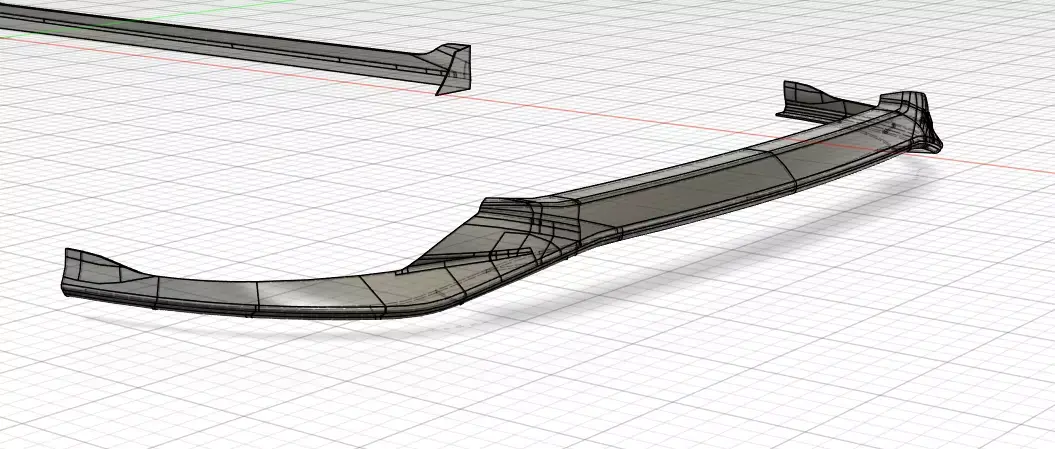

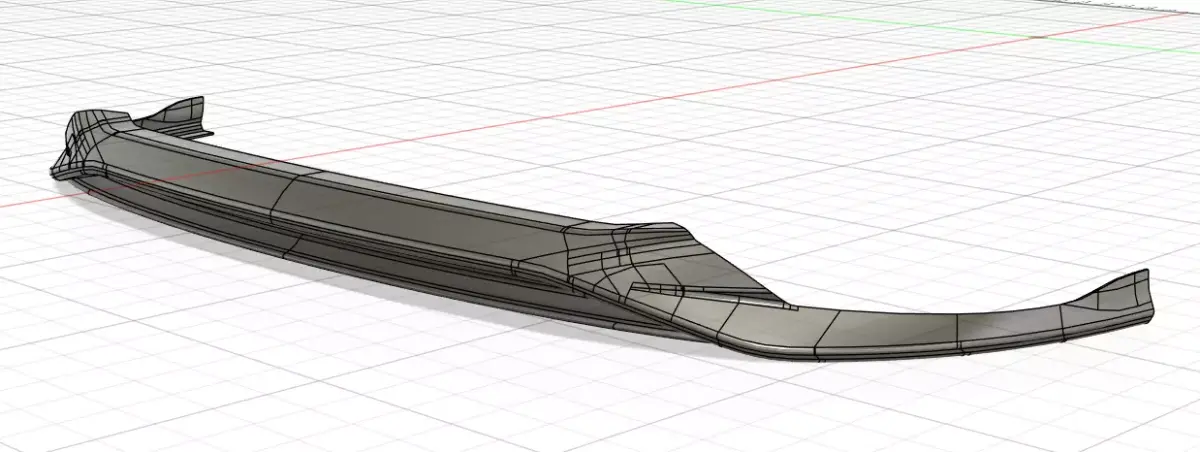

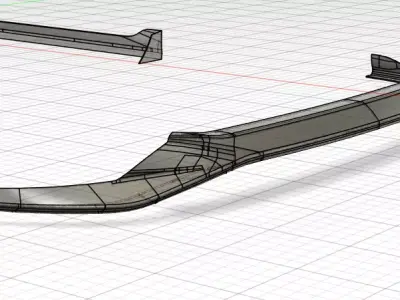

This listing is for high-quality digital 3D models (STL files) of a custom front lip splitter and matching side skirt extensions, designed specifically to contour the body lines of the modern Mazda 3 Hatchback.These parts were designed with a focus on aggressive street styling, giving the car a lower, wider, and more track-focused stance without needing to replace entire body panels.As seen in the reference renders, these parts look incredible when finished with a forged carbon fiber texture, but can be painted or wrapped to match any build.

Design Features:

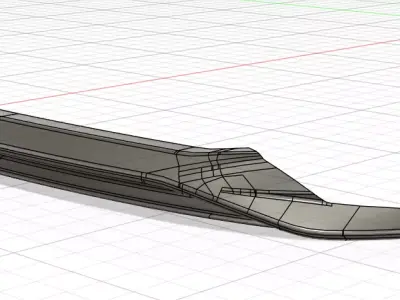

- Front Lip Splitter: A multi-contoured design that attaches beneath the factory front bumper. It adds significant visual depth and a sharp, aerodynamic leading edge.

- Side Skirt Extensions: These pieces install beneath the existing rocker panels. They feature a sleek profile along the side that terminates in an aggressive, upturned rear winglet/fin just before the rear wheel well, tying the side profile to the rear of the car.

- Perfect Fitment: Designed specifically using scan data/accurate referencing of the Mazda 3 BP Hatchback bumper and rocker panels for a flush, OEM-plus style fit.

Technical Specifications & Printability:

- File Formats Included: .STL, FBX & STEP

- Geometry: High-poly, watertight, and manifold geometry optimized for successful 3D printing.

Printing Recommendations:

- Material: For prototyping or scale models, PLA/PETG is fine. For functional automotive prototypes intended for road testing, ASA, ABS, or Nylon is highly recommended due to heat and impact resistance.

- Sizing: Due to the length of actual car parts, these models may need to be split within your slicer software (e.g., Meshmixer, Cura) to fit standard desktop FDM printer beds (like an Ender 3 or Prusa i3), and then glued/bonded post-print. Large-format printers may print sections whole.

- Scale: The files are modelled at 1:1

PLEASE NOTE:

- This listing is for DIGITAL FILES ONLY. No physical parts will be shipped.

- The printed parts will be the color of your filament and will require post-processing (sanding, filling, painting, or hydro-dipping) to achieve the desired finish.