Description

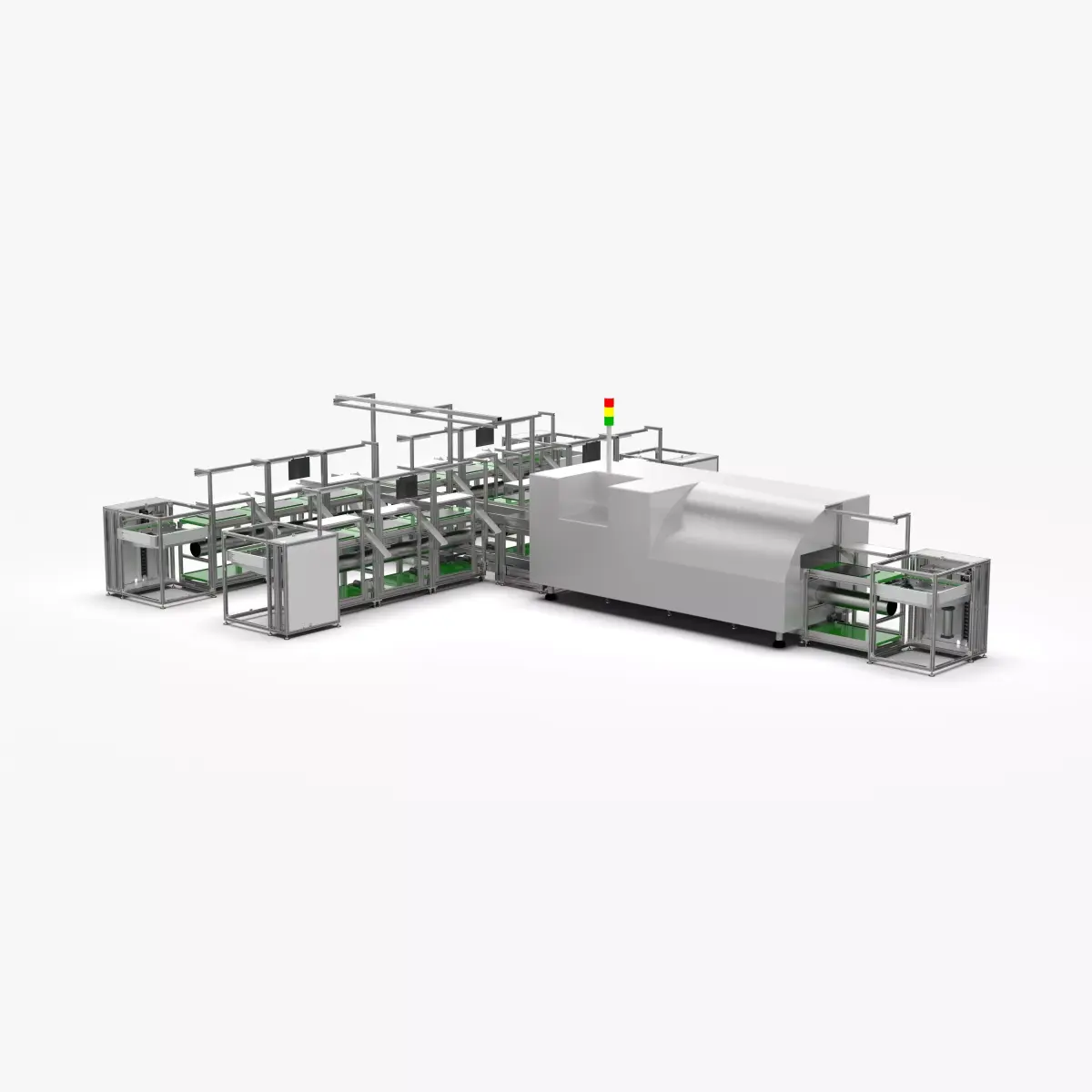

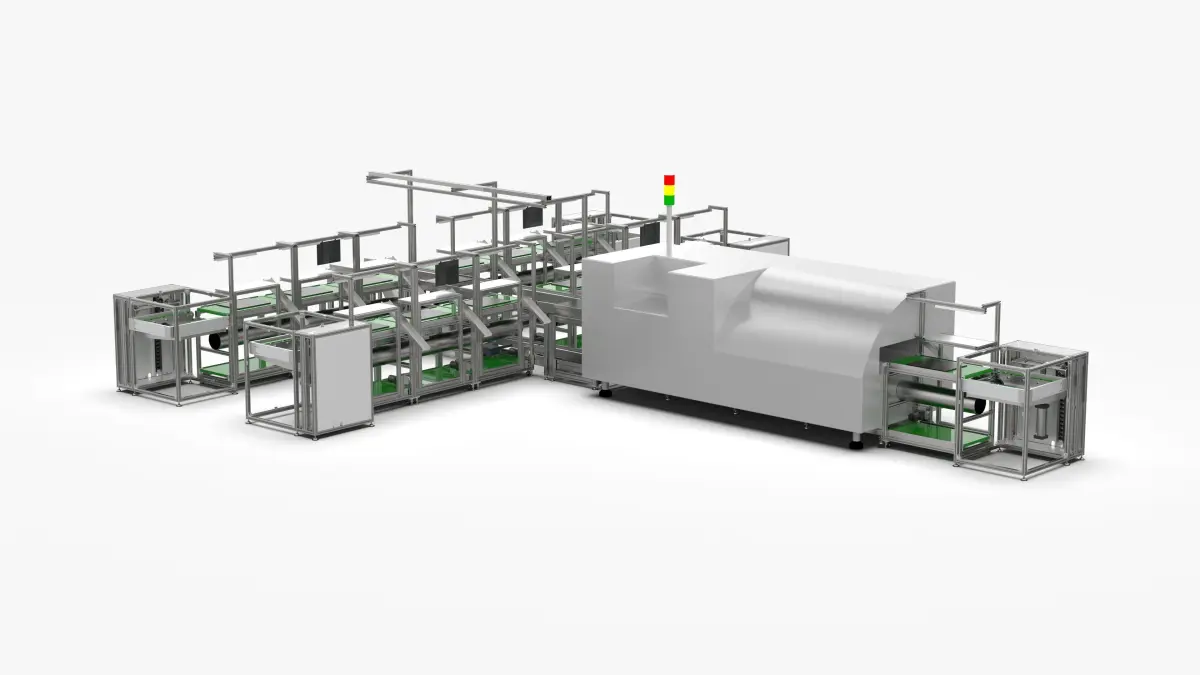

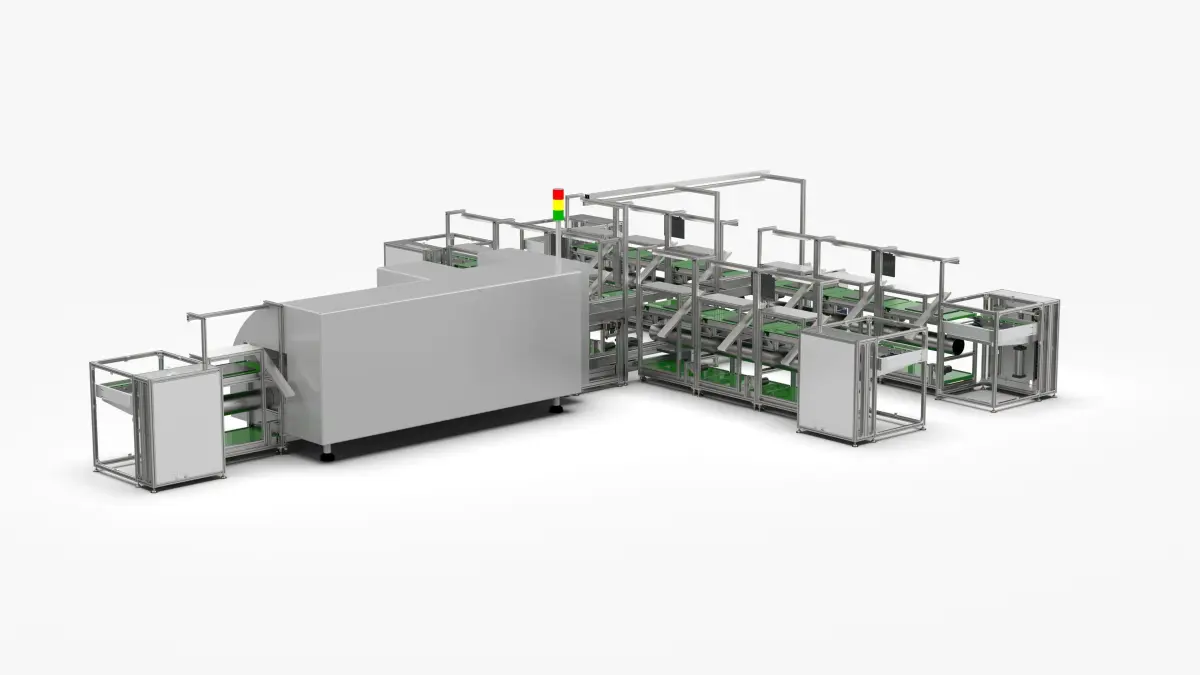

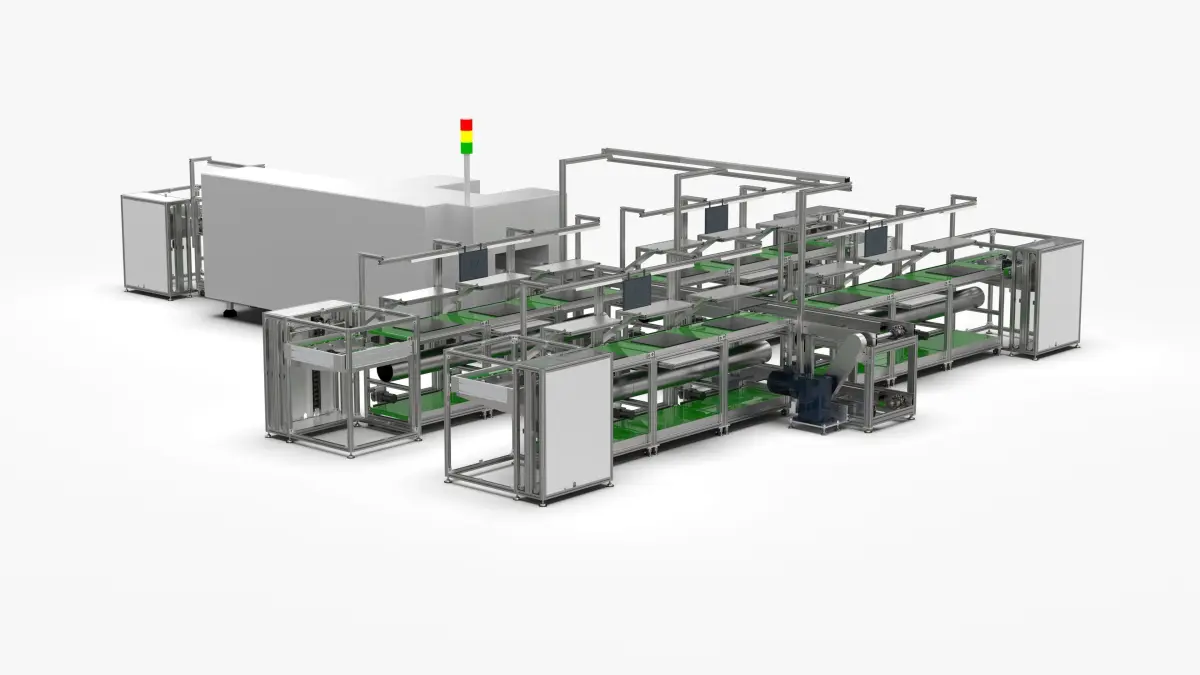

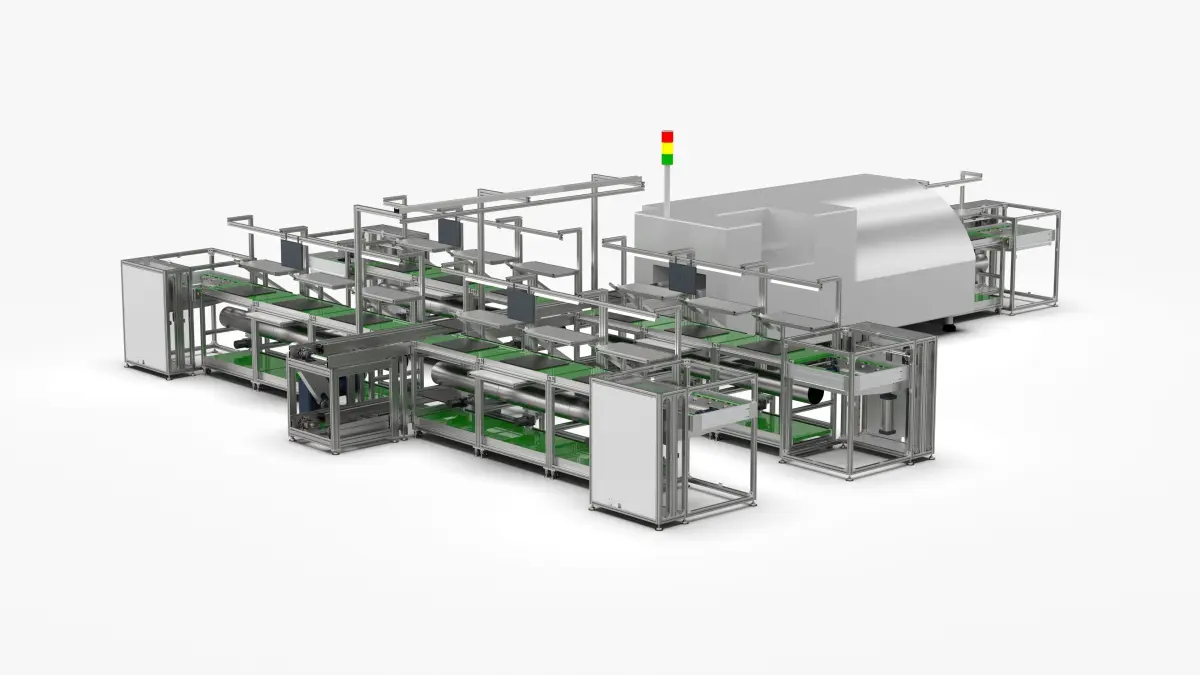

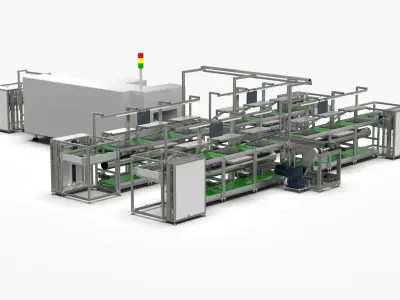

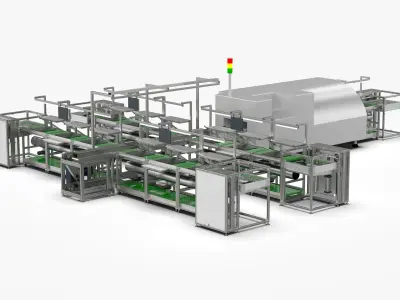

Selective Soldering Production Line

Introduction

Plug-in welding production line

- Adopt the method of passing tin furnace to realize the simultaneous passing of multiple PCBs of different styles.

- Use the up and down walking plate type.

- After the product is welded, when the fixture is returned to the board, it will automatically return to the corresponding position according to the type of barcode.

- There is no moving action after the plug-in is completed, and the direction of the plug-in is 90 degrees to the direction of the furnace.

- The line body is modularized, that is, each branch line can be combined at will under the condition that the site is not restricted.

- There is a clamp protection cover at the position of the working pedal to prevent the clamp from being damaged.

- The plug-in material rack adopts a double-layer design, and the plug-in material box has a recycling function.

- The lighting adopts integral lampshade lighting.

- Add an exhaust duct and integrate it into the line body, and use a splicable duct.

- One of the workbenches in each set of plug-in lines has a concealable workbench, which can realize thedual functions of plug-in/holding tin.

- Each plug-in station has a monitor to display the indicator card.

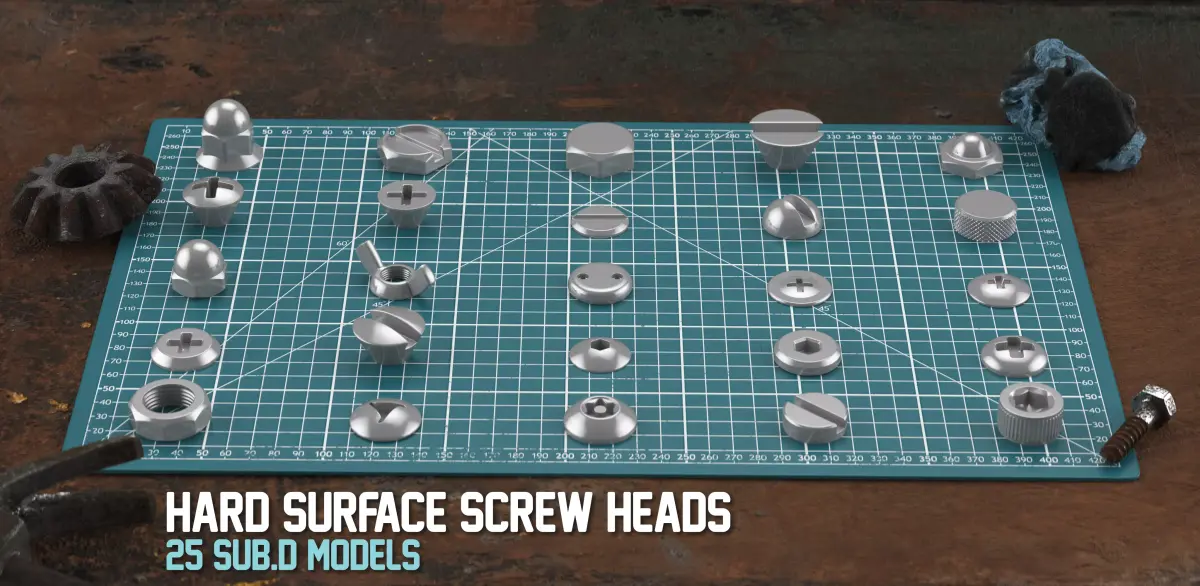

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 7,377,514

- Vertice: 22,132,542