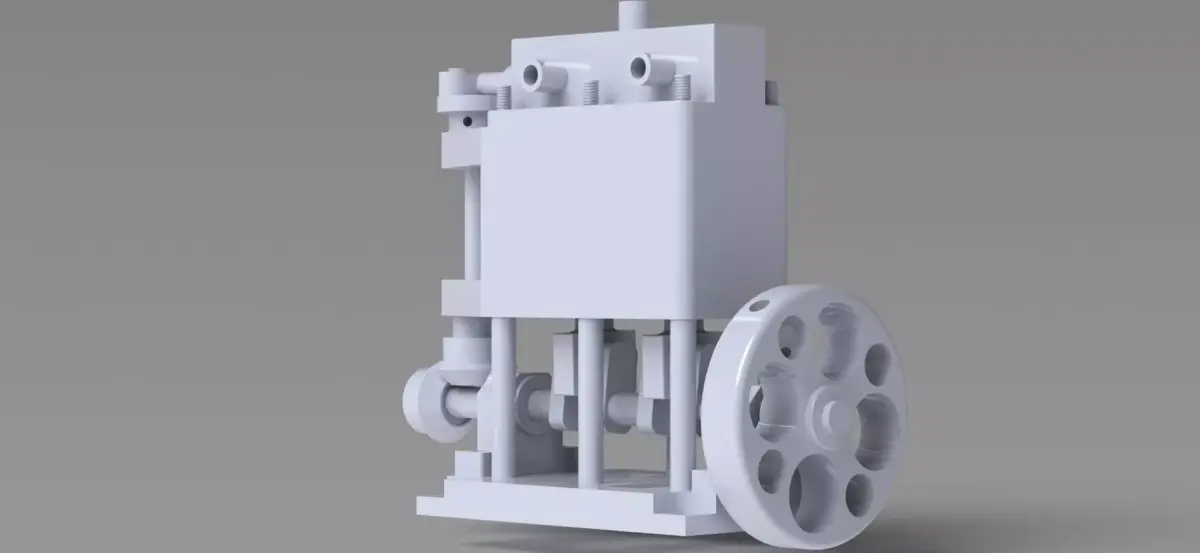

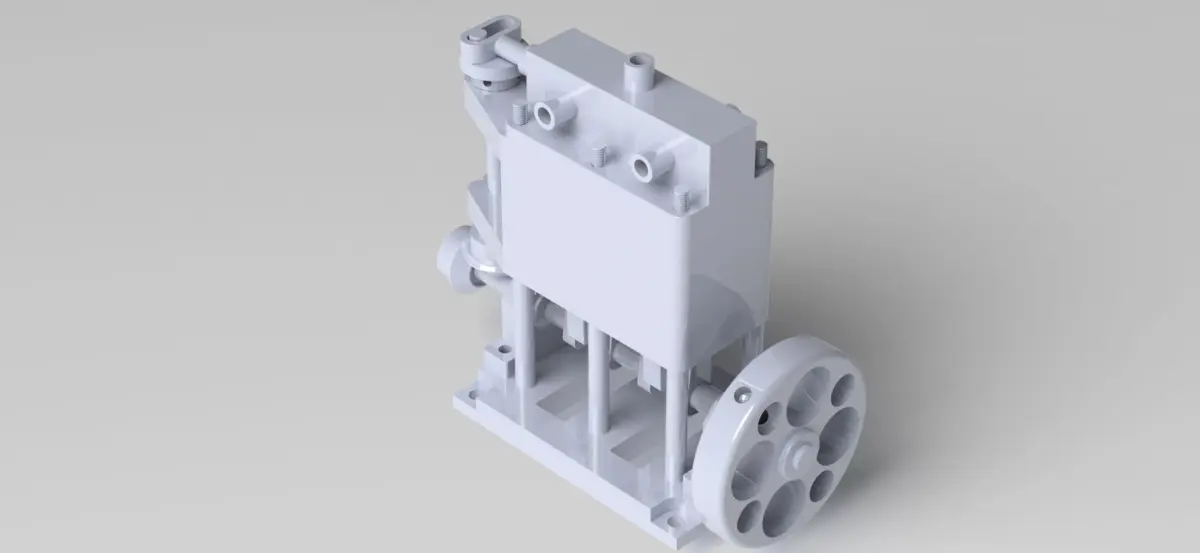

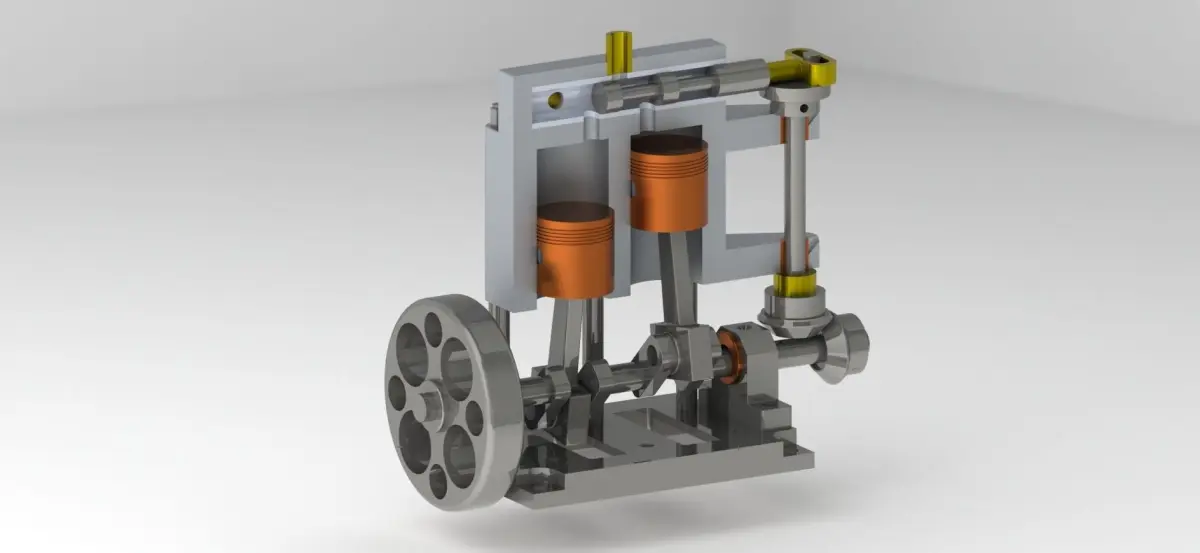

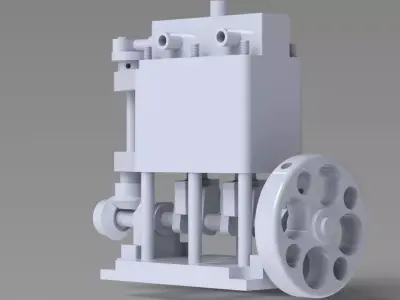

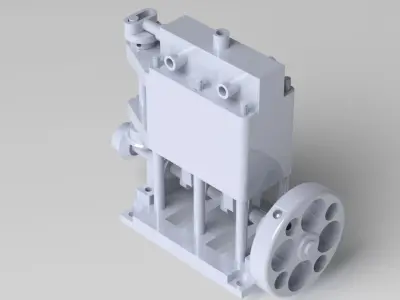

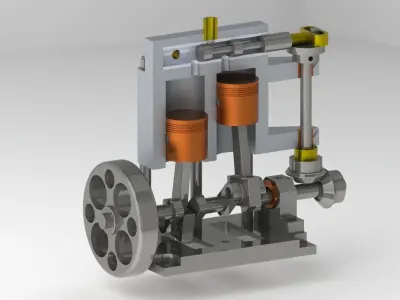

simple 2 cylinder vertical steam enginesolidwork part modelling and assemblysolidwork motion studysolidwork section view#machine_animation#steamengines

#SolidWorks#letsmakeitcadA simple 2-cylinder vertical steam engine is a basic mechanical device that converts steam pressure into rotational motion. Here's a description of how it works:

Components:

Cylinders: There are two vertical cylinders, usually placed side by side.Pistons: Each cylinder has a piston that moves up and down within it.Crankshaft: The two pistons are connected to a common crankshaft, which converts the reciprocating (back-and-forth) motion of the pistons into rotational motion.Flywheel: A heavy flywheel is attached to the crankshaft. It stores rotational energy and smoothens out the engine's motion by providing momentum.Working:

Steam Inlet: Steam is admitted into one end of the cylinder through a valve.Expansion: The steam enters the cylinder and pushes the piston upwards. This is the power stroke. As the steam expands, it cools down and loses pressure, while its energy is transferred to the piston's movement.Exhaust: After the power stroke, a valve opens to allow the used steam to exit the cylinder.Piston Return: As the used steam is expelled, the piston is pushed back down by the flywheel's momentum or sometimes by a counterweight. This is the exhaust stroke.Steam Switch: At the same time, the second cylinder goes through a similar cycle. While one cylinder is in the power stroke, the other cylinder is in the exhaust stroke, and vice versa. This arrangement ensures a continuous rotational output.Advantages:

Simplicity: A basic two-cylinder design is relatively straightforward in terms of construction and operation.Compactness: Vertical steam engines can be more compact than horizontal ones, making them suitable for certain applications with limited space.Disadvantages:

Efficiency: These simple engines might not be as efficient as more complex designs, as they lack features like variable valve timing and other mechanisms for optimizing steam usage.Limited Power: While suitable for certain applications, this type of engine might not generate high levels of power compared to more advanced designs.Remember, this is a simplified overview. Actual steam engine designs can vary in complexity and features. If you're considering building or working with a steam engine, it's important to have a deep understanding of steam mechanics, safety measures, and engineering principles.